I've been taking advantage of the nicer days as much as I can and pushing forward. I have most of the front end pieces for the Rough Country 5" kit installed but unfortunately it took some time because there was hardware missing where I had to improvise. I'm not very impressed with that considering the cost of the kit. At least it was only nuts and bolts and not something more critical. In putting together the torsion keys though I noticed that my dampers or isolators or whatever they are called were toast so I had to stop and get some ordered. They seem to be a bit difficult to find but they're out there.

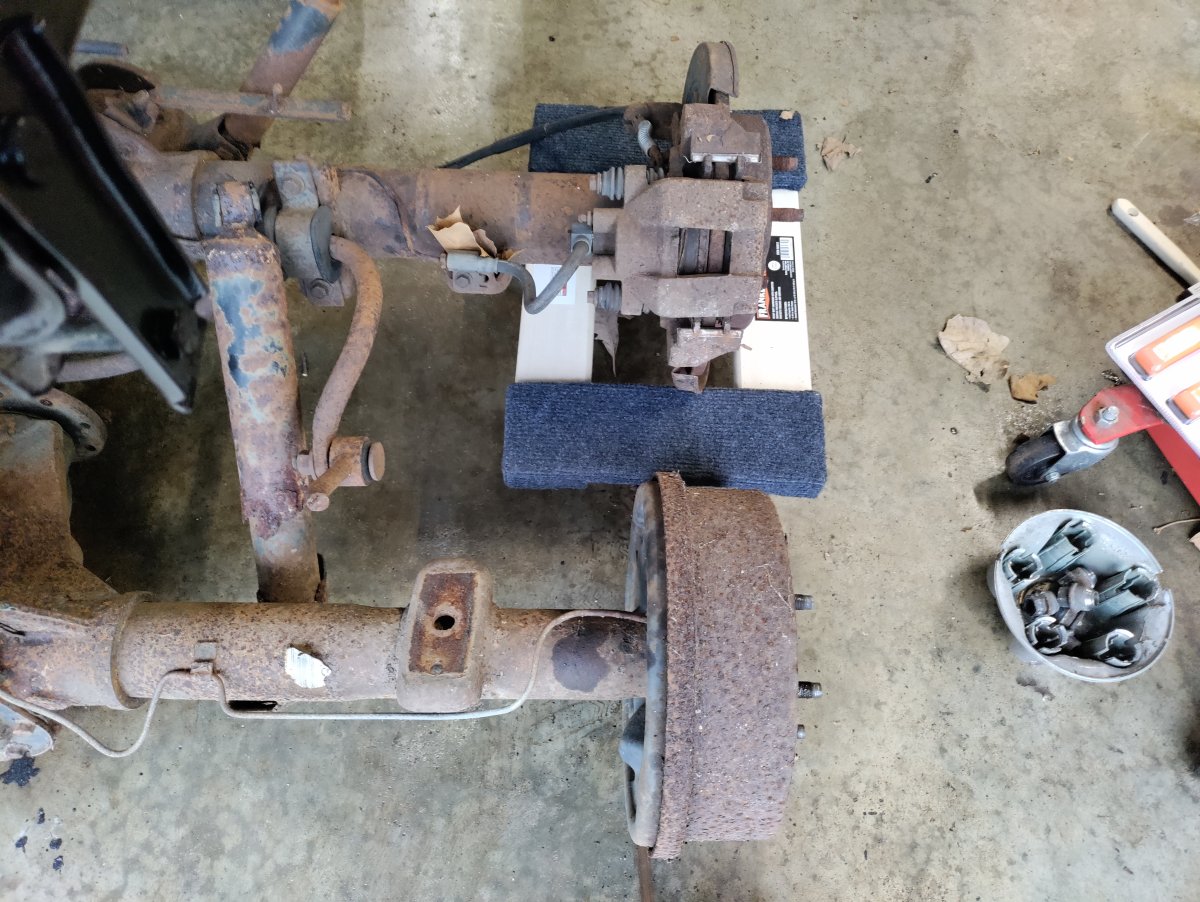

Pressing the bushings out of the lower control arms gave me all sorts of grief. I am lucky that the new bushings are fairly durable because I had to misuse my ball joint press pretty bad to get them replaced. I'm also lucky Harbor Freight released a ball joint expansion kit because without it I would've been lost with my standard pieces. To save money I am reusing as much original equipment as I can get away with so many items in the picture below are actually old but have been wire wheeled and painted. Rustoleum Hammered black is a pretty solid choice IMO. It's cheap and it dries extremely quick. As someone who really hates painting, I use it for just about everything.

Two of the biggest items left for me were cleaning up the front differential and getting the rear axle converted to bolt up to a Ranger instead of Explorer. After an hour or so of scrubbing and degreasing I got the front diff "good enough" and slapped it with some paint. I tried to get some aluminum colored high-heat paint from the local Menards but it was the

only spray paint that was sold out that day. I ended up with some silver extreme heat and didn't realize that it was metallic. Unintentionally I now have a glitter diff. Too late to go back now. There are extremely few results on google for "painting a front diff" and most people opt not to do it or just do the cover. I decided to full send and paint the whole thing and we'll see what sticks. Is there a reason nobody seems to paint aluminum? We're going to find out. Did I mention I hate painting? As a side note: I've googled as hard as I can and haven't found anyone local who does blasting and powdercoating to make it worth my while to drive to. I would love to have these pieces done for me and I hate painting enough to pay for it. When I was calling around for the frame to be powder coated, the most likely place to do it said they were on a 3 week waiting period that started when I dropped it off and I can't get in line before then. I hate waiting more than I hate painting and since that left a bad taste in my mouth here we are with a glitter diff. From here on out I'm going to say it was on purpose. I'd also like to point out that while I intend to baby it while in 4wd, if I ever decide to give it the beans I imagine I may blow up the front diff which is why I'm not being very kind to it, just like I imagine the first 200k on it weren't.

While I wait for parts to come in I'm going to work on the Explorer axle and get that prepped and welded with new perches. To help anyone in the future, I've pictured the two right next to each other to compare. I got mine off the Facebook Marketplace and I believe the guy said it was a '99 Explorer 4.10 (on dollys) vs my original (on the floor). I was worried the Explorer would be a little wider but that doesn't seem to be the case. I am extremely excited to finish up the suspension and get this sitting back on the ground. Once that's done I can place the drivetrain again. Since I've already made the mounts it should go in quickly. Since pretty much the whole interior and exterior of the truck is laying in parts on the garage floor at the moment, the more I can complete, the less time I spend tripping on things and carefully maneuvering the tools I need around it all.

Lastly, I'd like like to remind everyone to stay safe out there. I ran into one of my best buds at the Harbor Freight today I haven't seen in a while. He told me he had just got out of the hospital after being crushed by a car that rolled off the ramps while he was working under it. If you're going to do something sketchy, remember to take safety super serious. Never place any part of yourself under something that can crush you, and make sure to wear your ear, eye, and hand protection. Buy an automotive fire extinguisher and have it near. Keep your phone on you instead of on the work bench, even if it keeps falling out of your pocket while crawling on the ground.

Whatever you need to do to take one more precaution you didn't think you needed, DO IT. I've spent a good amount of my tool money on safety equipment and it pays dividends when something goes wrong and you don't have a hospital or funeral bill to deal with. No joke there is probably at least one thing per week that flies into my face shield or gloves at high speed that would certainly be a hospital run without them. There was actually debris when cleaning my diff that flew

under my face shield and was only stopped by my glasses. In my travels I've had two vehicles fall off jackstands myself that could've caused "issues" had I not been elsewhere at the time. It can happen to anyone. No Ranger project is worth anything if you're not around to complete it. Rant over and looking forward to finishing this up!