Jbrown1238

Member

- Joined

- Sep 3, 2010

- Messages

- 691

- Reaction score

- 6

- Points

- 18

- Location

- Largo, Fl

- Vehicle Year

- 2003

- Make / Model

- Ford

- Engine Size

- 306

- Transmission

- Manual

- My credo

- None

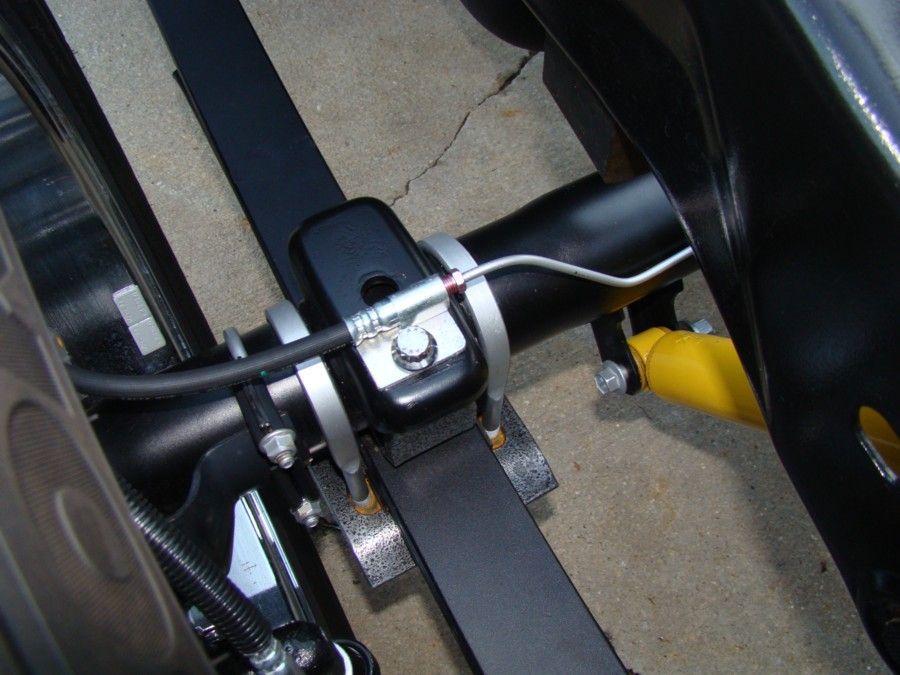

Thank you for the heads up and the kind words. I did some preliminary measurements and it looked like the 99 3.0 V6 automatic regular cab Ranger drive shaft was a little short. However the one from my second truck, a 98 2.5L manual trans regular cab Ranger looked very close to the right length. I have a yoke from a 93 cobra that I plan to use but have not matched it to the driver shaft yet.very nice built....if you haven't done your drive shaft, I like to share my build.

I use one from 2000 2wd v8 explorer just change yoke with the one from my 99 ranger and fit perfect.