kishy

Active Member

- Joined

- Jan 9, 2018

- Messages

- 148

- Reaction score

- 58

- Points

- 28

- Location

- ON, Canada

- Vehicle Year

- 1985

- Make / Model

- Ranger, RCLB

- Engine Size

- 95 2.3 EFI Swap

- Transmission

- Manual

- 2WD / 4WD

- 2WD

Hi folks!

To recap on my brief history here at TRS...

I initially came here seeking to know if I could use 2.3 parts to EFI swap my existing 2.0: http://therangerstation.com/forums/showthread.php?t=175086

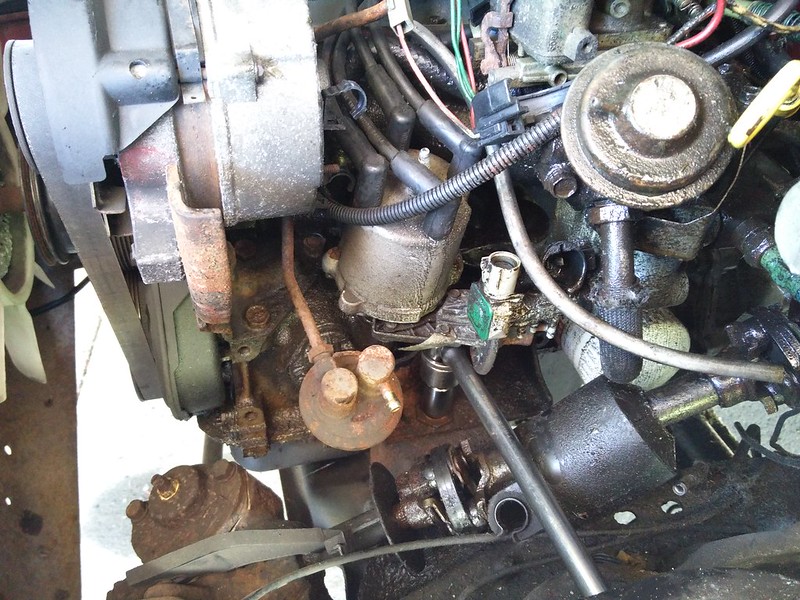

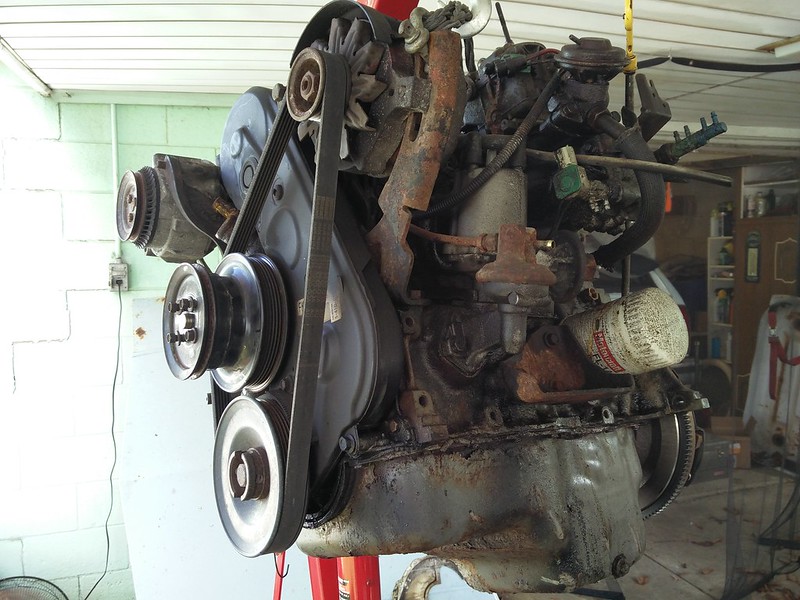

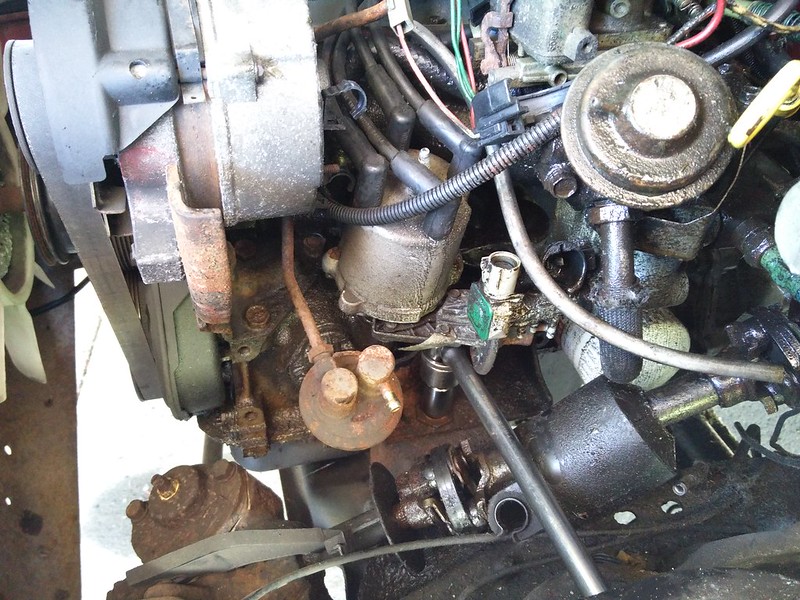

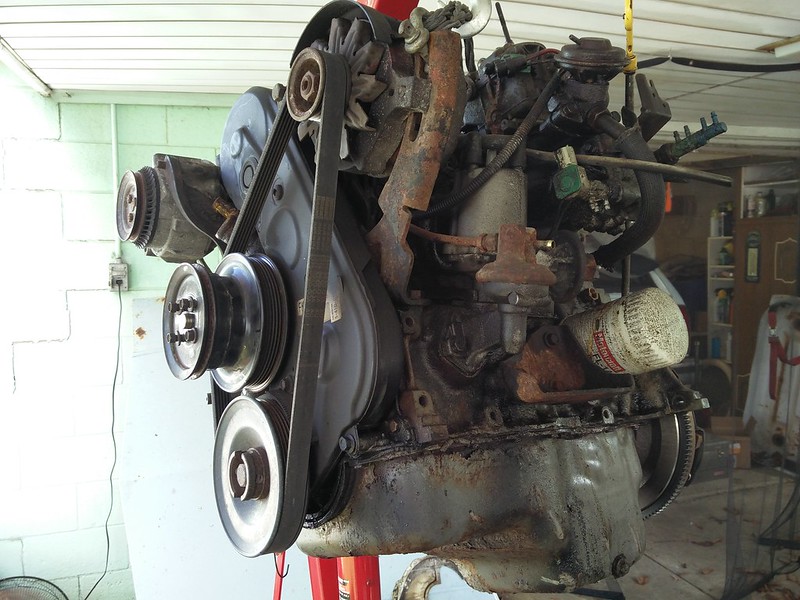

But I encountered a few too many unknowns to want to risk that, and came across a supposedly nearly-new 2.3 (F5 part numbers, is a 95+ 2.3 Lima, but is set up like a 93-94 EEC-IV example) which I inquired about here: http://therangerstation.com/forums/showthread.php?t=175138

The existing 2.0 has serious oil consumption issues (around a quart per hour of runtime and visibly smokes under all conditions) and the carb has a worn throttle shaft causing an uncorrectable vacuum leak, so the logical choice was to just ditch this engine entirely.

I have been quietly hunting parts, mapping wires, and mentally preparing to do this engine swap to get rid of my 2.0. We're finally here, ish.

---

First, I needed to figure out a way to mount an EFI high pressure pump. My preference was to put it in the tank like most vehicles from the 80s onwards do, although there are some exceptions, notably some but not all Fords (including the Ranger until 1988).

I determined that my exact same fuel tank (which I purchased new in 2015 - Spectra F21C) was used through 1988, after which a new tank was introduced. I went to a junkyard to check if a 1988 2.3 EFI truck used the same tank and found it did. This meant I could salvage its fuel sender, which would gain me a return line (needed for EFI) and the hanger for the in-tank pump.

1988 still uses two pumps, and the one inside the tank is very small. However, I bought a Carter P74123 pump which is also very small despite being a normal EFI pump, and was able to make it fit. I had to recondition the contacts in the fuel gauge sender as it had a lot of opens and high resistance spots which would make the gauge unreliable. I tested the new sender with my existing cluster and verified it behaves well, before committing to installing it. I also replaced the wires on the sending unit which feed the pump, because the old ones for the low pressure lift pump seemed a little thin.

With this, I will be able to use 1993-scavenged plastic fuel lines to feed the fuel rail which is also a 1993 part.

The tank came out and the sender went into the tank yesterday 9/14. The tank is still outside the truck as I felt it would be best to have room to move around under there for mating the transmission to the engine post-swap.

---

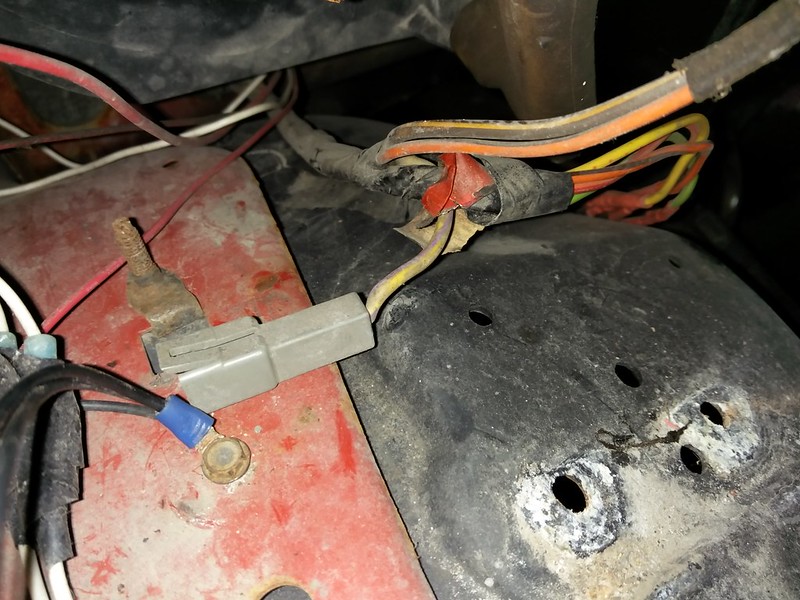

Today, I replaced the starter relay (aka solenoid). This is important because the original installed on my truck is the old-school vertical style with a D8 part number, which does not have a flyback diode within. Flyback diodes were added to the design beginning in the 80s for EFI vehicles because a relay not so-equipped can damage electronics like the ignition module or ECM. The new relay will avoid that. I made sure after doing this that all vehicle electronics including the starter circuit work, so if there is a starting issue after the swap, at least I know this is working correctly.

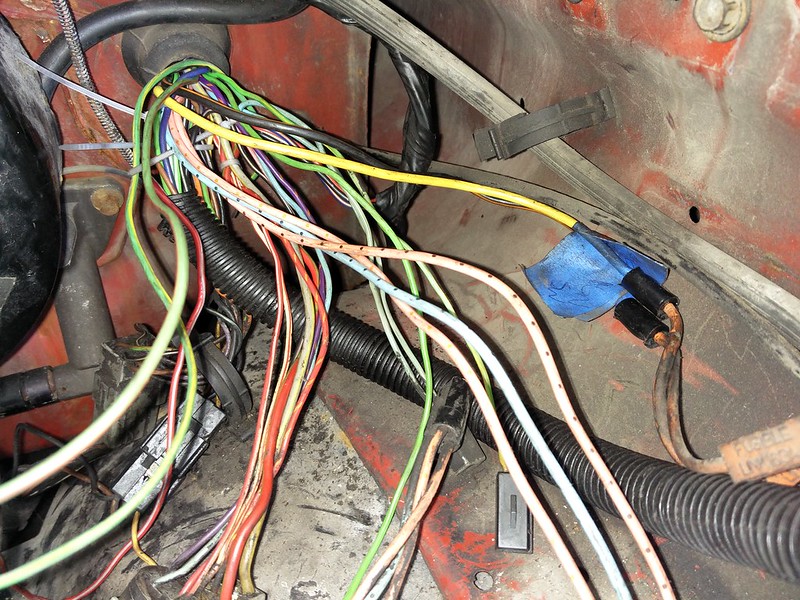

I drained the coolant and oil. Removed the air intake tube and air cleaner. Removed the radiator. Removed the idle speed computer, Duraspark module, and ignition coil. Removed the engine harness (note to self - this contains the reverse light switch pigtail, if different from the one on the 93 harness). Removed the fan clutch and fan, hoping to reuse these on the new engine.

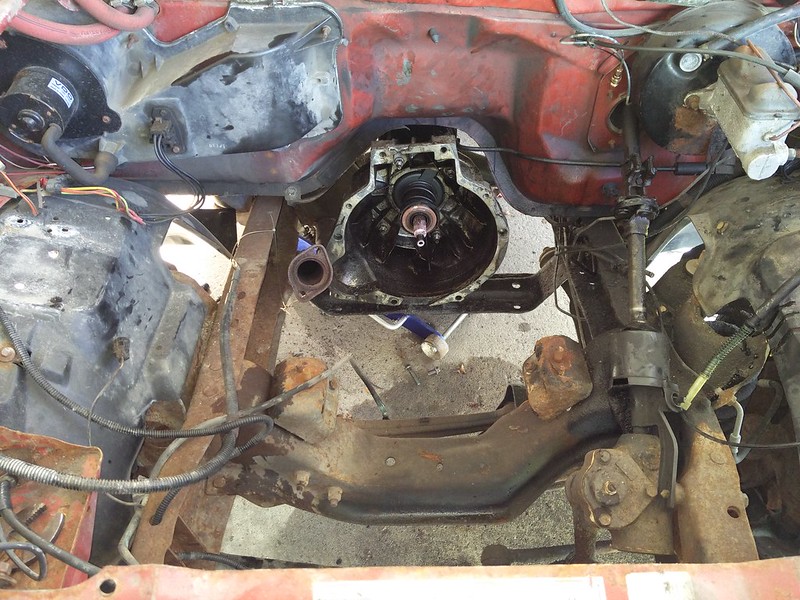

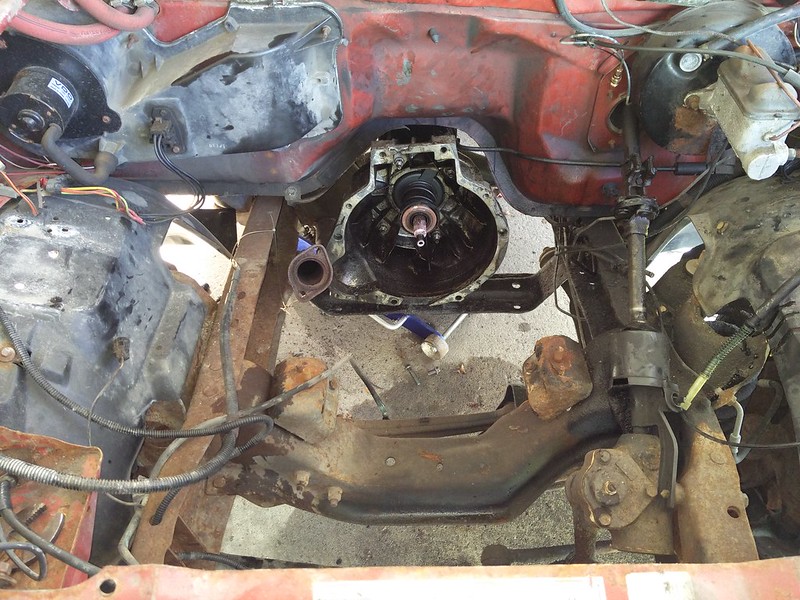

Unbolted engine mounts, unbolted trans from engine, unbolted exhaust bolts (one came out clean, one snapped off). Put a jack under the trans, then hooked my engine crane to the 2.0 and gave it a tug. Popped out pretty easily. Removed the engine mount brackets from the old engine as I need to reuse those, but I will use new actual mounts. Also knocked out the bellhousing alignment dowels (hollow metal tubes at the leftmost and rightmost bolt holes for aligning trans properly) because my new engine lacks them.

I am currently on a bit of a break from the heat and to grab some food. Next steps will likely involve cleaning the engine bay and finding all the wires I need to connect things to. The new engine may go in by the end of the weekend but probably won't. I suspect I'll appreciate having the extra room to work for making wiring alterations.

To recap on my brief history here at TRS...

I initially came here seeking to know if I could use 2.3 parts to EFI swap my existing 2.0: http://therangerstation.com/forums/showthread.php?t=175086

But I encountered a few too many unknowns to want to risk that, and came across a supposedly nearly-new 2.3 (F5 part numbers, is a 95+ 2.3 Lima, but is set up like a 93-94 EEC-IV example) which I inquired about here: http://therangerstation.com/forums/showthread.php?t=175138

The existing 2.0 has serious oil consumption issues (around a quart per hour of runtime and visibly smokes under all conditions) and the carb has a worn throttle shaft causing an uncorrectable vacuum leak, so the logical choice was to just ditch this engine entirely.

I have been quietly hunting parts, mapping wires, and mentally preparing to do this engine swap to get rid of my 2.0. We're finally here, ish.

---

First, I needed to figure out a way to mount an EFI high pressure pump. My preference was to put it in the tank like most vehicles from the 80s onwards do, although there are some exceptions, notably some but not all Fords (including the Ranger until 1988).

I determined that my exact same fuel tank (which I purchased new in 2015 - Spectra F21C) was used through 1988, after which a new tank was introduced. I went to a junkyard to check if a 1988 2.3 EFI truck used the same tank and found it did. This meant I could salvage its fuel sender, which would gain me a return line (needed for EFI) and the hanger for the in-tank pump.

1988 still uses two pumps, and the one inside the tank is very small. However, I bought a Carter P74123 pump which is also very small despite being a normal EFI pump, and was able to make it fit. I had to recondition the contacts in the fuel gauge sender as it had a lot of opens and high resistance spots which would make the gauge unreliable. I tested the new sender with my existing cluster and verified it behaves well, before committing to installing it. I also replaced the wires on the sending unit which feed the pump, because the old ones for the low pressure lift pump seemed a little thin.

With this, I will be able to use 1993-scavenged plastic fuel lines to feed the fuel rail which is also a 1993 part.

The tank came out and the sender went into the tank yesterday 9/14. The tank is still outside the truck as I felt it would be best to have room to move around under there for mating the transmission to the engine post-swap.

---

Today, I replaced the starter relay (aka solenoid). This is important because the original installed on my truck is the old-school vertical style with a D8 part number, which does not have a flyback diode within. Flyback diodes were added to the design beginning in the 80s for EFI vehicles because a relay not so-equipped can damage electronics like the ignition module or ECM. The new relay will avoid that. I made sure after doing this that all vehicle electronics including the starter circuit work, so if there is a starting issue after the swap, at least I know this is working correctly.

I drained the coolant and oil. Removed the air intake tube and air cleaner. Removed the radiator. Removed the idle speed computer, Duraspark module, and ignition coil. Removed the engine harness (note to self - this contains the reverse light switch pigtail, if different from the one on the 93 harness). Removed the fan clutch and fan, hoping to reuse these on the new engine.

Unbolted engine mounts, unbolted trans from engine, unbolted exhaust bolts (one came out clean, one snapped off). Put a jack under the trans, then hooked my engine crane to the 2.0 and gave it a tug. Popped out pretty easily. Removed the engine mount brackets from the old engine as I need to reuse those, but I will use new actual mounts. Also knocked out the bellhousing alignment dowels (hollow metal tubes at the leftmost and rightmost bolt holes for aligning trans properly) because my new engine lacks them.

I am currently on a bit of a break from the heat and to grab some food. Next steps will likely involve cleaning the engine bay and finding all the wires I need to connect things to. The new engine may go in by the end of the weekend but probably won't. I suspect I'll appreciate having the extra room to work for making wiring alterations.