- Joined

- Jul 16, 2008

- Messages

- 291

- Reaction score

- 11

- Points

- 18

- Location

- Bridge City, Texas

- Vehicle Year

- 1996

- Make / Model

- Ford

- Engine Type

- 4.0 V6

- Transmission

- Automatic

- 2WD / 4WD

- 4WD

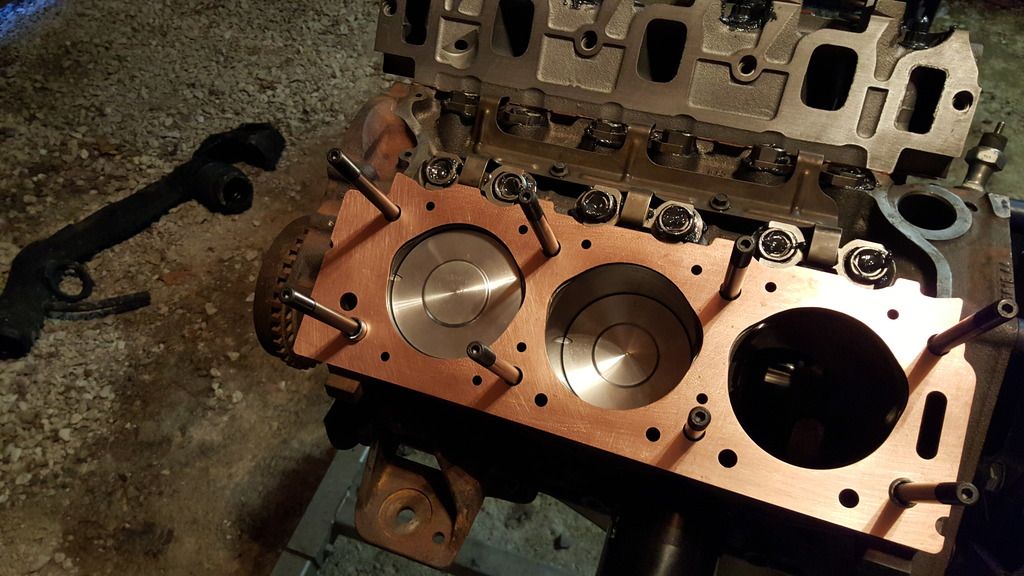

rebuilt heads

stellite exhaust seats, new valve springs (stock), 3 angle valve job

Proform roller rockers 1.7:1

These rockers have 5/16 in bolts which will need to be replaced. I've read about tapping the heads for 5/16" threads but i would recommend against doing so. The difference between M8 and 5/16 isn't enough to provide a "clean" thread tap... 5/16 is 0.3125" where M8 is 0.3150". The only thing accomplished is the removal of a thread... and the fit is questionable. Instead buy a M8-1.25 x 140 crown head bolt. This is the exact thread and proper length to bolt these rockers on right the first time. It goes without saying, make sure the fulcrum is positioned correctly, it is machined with a flat surface which the head of the bolt mates against. It is very easy to install the rocker with the fulcrum upside down... sounds dumb yes... but easy to do. Double checking your work is a good idea.

Last edited: