Cncproformance

New Member

- Joined

- Apr 19, 2014

- Messages

- 19

- Reaction score

- 0

- Points

- 0

- Vehicle Year

- 1988

- Make / Model

- Ford

- Engine Size

- 2.3 to 5.0

- Transmission

- Manual

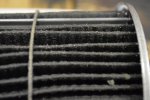

Backround: Built a 347 for my 88 Ranger. Eagle rotating assembly (fully forged), Clevite bearings, March Serpentine kit, TCI 157 tooth flexplate, TCI 3,000 stall Torque Converter and TCI C4 Transmission (Auto Valve Body). Crankshaft endplay was set to 0.005. Dropped the motor in, properly broke in and at the 300 mile mark changed oil and cut open the filter to find normal break-in shavings and copper. Immediately Ripped the motor out and the thrust bearing was ate up badly. No other bearings showed any abnormal wear. The crankshaft had almost 0.014 endplay. Installed new thrust bearing and re-set endplay to 0.005. Re-installed the motor. Grounded it out properly, it has a single trans cooler which is not linked to the radiator at all and all lines are free of kinks. After starting it up and doing a few electrical tests and some free revving for a few days, removed the filter to find no copper what so ever. (Note: Did not drive truck at all during this time. Never went into gear). Installed new filter, drove it for about an hour and removed the filter. Cut it open and found glorious copper. I hooked my Go-Pro to the oil pan to take a video of the converter while driving around the block. While under a 2,000 rpm load it appears this thing is moving quite a bit. I rechecked endplay and its now at 0.008. Also, while cranking, I noticed the flexplate would wobble more than I would like to see. All parts are new out of the box. Let me know if you need pictures of what the old thrust bearing and filter looked like. I'll send them over as requested along with the video. What would be causing the premature wear of the thrust bearing?

Last edited: