My link mounts are directly below my frame, so my clearance issue isn't with the frame rails either, its with the sliders and the body mounts... I just got my track bar tacked together so Ill do some more cycling of the suspension and see what I have clearance wise...

I can do 1.75 1/4 DOM with mine, just not 2", and I guess neither can anyone around in a 20 mile radius to me, except for 1 exhaust shop...

Good to know about the HF one though, because I have a friend with one...

Got some more stuff in the mail

They are the wildhorse 5.5 rockcrawler springs

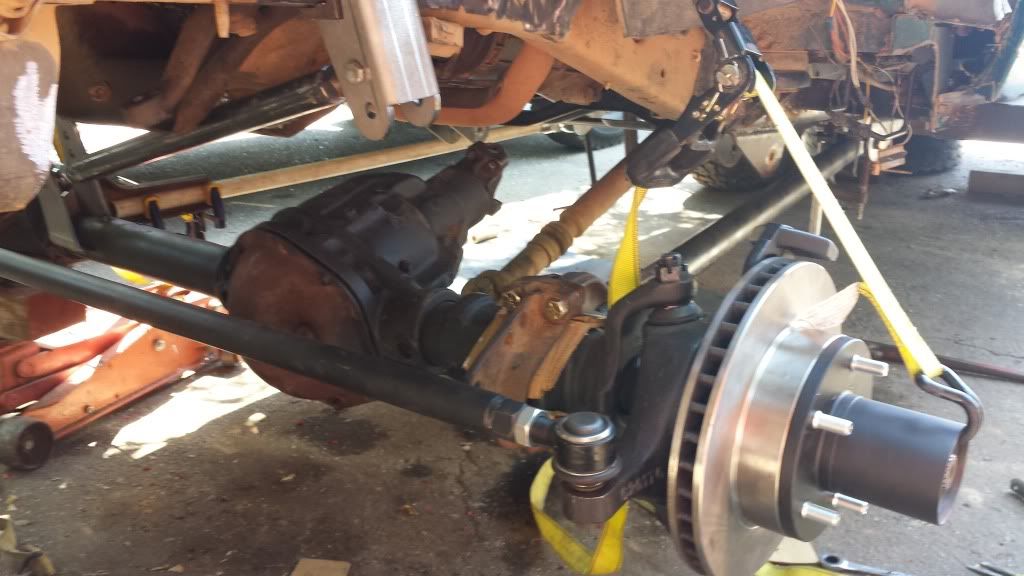

After mock up with pvc, I got started on the track bar

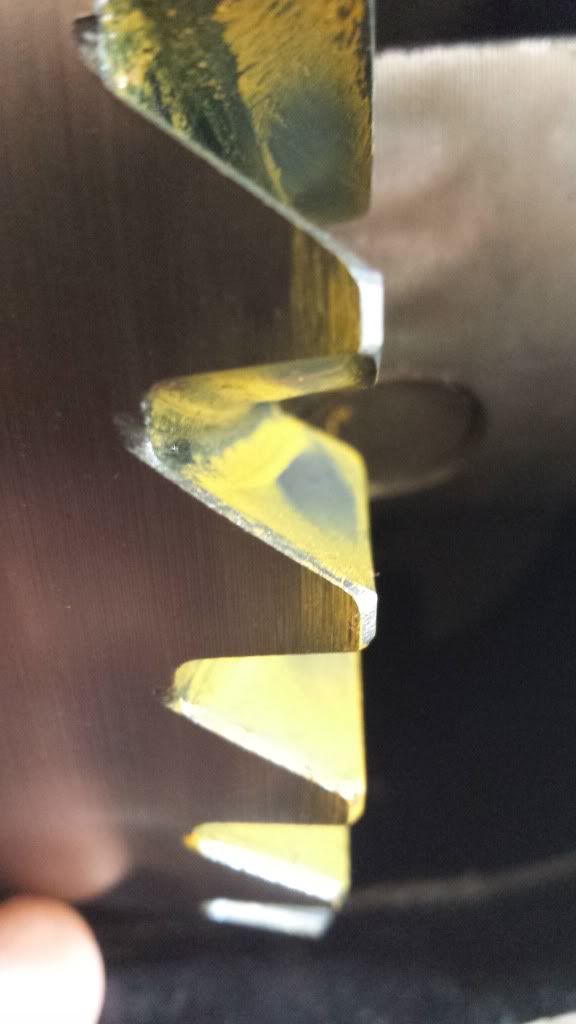

Penetration on first pass on the bung

and got the track bar mounts tacked in

Frame side didn't lay out so well, so I added a piece of metal to fill the gap. It is 1/2 steel, so I think it should be plenty strong, and I made it in such a way to have more area to weld onto the frame so it should actually be stronger. I hope.

The other side of the mount will be treated the same way

The strap is hooked below the pitman arm, and the left side is laying on top of the tie rod end, so its not an exact layout, but both sides should move down equally so it should be pretty accurate. Idk but IMHO I think that is looking pretty close. Anything should be way better than the bumpsteer I had with 6" lift and stock steering on my TTB...

Truthfully I thought it was still too shallow... Im not really sure on how to read the pattern on the pinion, but it seemed pretty centered peak to valley, but off center towards the base of the head a little. Towards the fatter part if you will. I guess that would indicate too deep? But it wasn't close enough to the base to worry me at the time IIRC.

maybe?